Category

- Heat resistance

- Thermocouple

- Double metal thermometer

- Integrated temperature transmi

- The temperature of the casing

Contact us

Company name: Anhui KERONE Instrument Co. Ltd.

Address: Anhui province Tianchang copper town industrial park two weft Road

Telephone:0550-2392658

Fax:0550-2392656

Contact:Manager Wang 18712409550

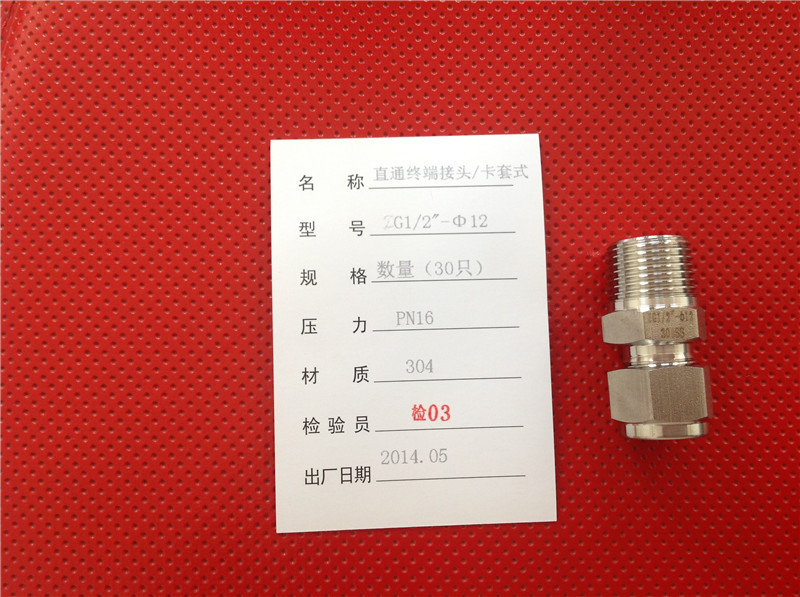

Through the terminal connector

DATE:2015-08-12 HITS:0

| Processing customized | yes | model | YZG1-1/YZG1-2 | The material | Stainless steel |

| Connection type | Card sleeve |

Steel connector of cutting sleeve type has the characteristics of connecting firm, high compression capacity, sealing and good repeatability, convenient installation and maintenance, safe and reliable work, etc

Material: stainless steel 304

Nominal pressure: 16 mpa 25 mpa

Applicable temperature: 200 degrees or less

Applicable medium: oil, water, gas and other non corrosive or corrosive medium

Piping: Φ 3 - Φ 42 regular grade precision seamless steel tube

Available for G terminal thread, mid-december, NPT, etc

The rest of the specifications, inch pipe, M, mid-december, such as NPT thread can be customized, huan drink to the masses of customers came to negotiate! Telephone: 18712409550, quantity is with preferential treatment.

Card sleeve pipe assembly method:

Pipe connector of cutting sleeve type has the performance of the good or bad in addition to materials and parts, manufacturing precision, heat treatment and so on, and the relationship between the assembly quality is also very important, so should be assembled as follows.

1, cut out the pipe length on the production machine as required. Can also be manual cutting, the plane perpendicular to the pipe centerline degrees shall not be greater than about half of the pipe location tolerance.

2, remove the tube end, burr, the cylindrical metal debris and dirt.

3, remove pipe joint in various parts of anti-rust oil and dirt.

4, in order to end, card set set on the pipe, and then insert the pipe joint in the body at the bottom of the cone hole, put is card sets. Screw the nut on the rotating tube until not moving at the same time, the screw nut 1 ~ 1 1/3 circle again.